Volatile components such as chlorine, alkali and sulfur in cement raw materials and fuels are concentrated in the circulation of the clinker production line. This circulation frequently causes problematic coatings forming low melting point compounds and affects the stable operation.

In recent years, the cement industry in the world has been promoting the utilization of alternative fuels and raw materials (AFRs), so as to protect the environment and to conserve resources.

Consequently, the utilization of AFRs has increased, and the volume of volatile components, particularly chlorine, in the clinker production line has increased as well. Therefore, a technology to remove chlorine effectively from the clinker production line was required. The TCBS has been developed as the most sophisticated way on this background.

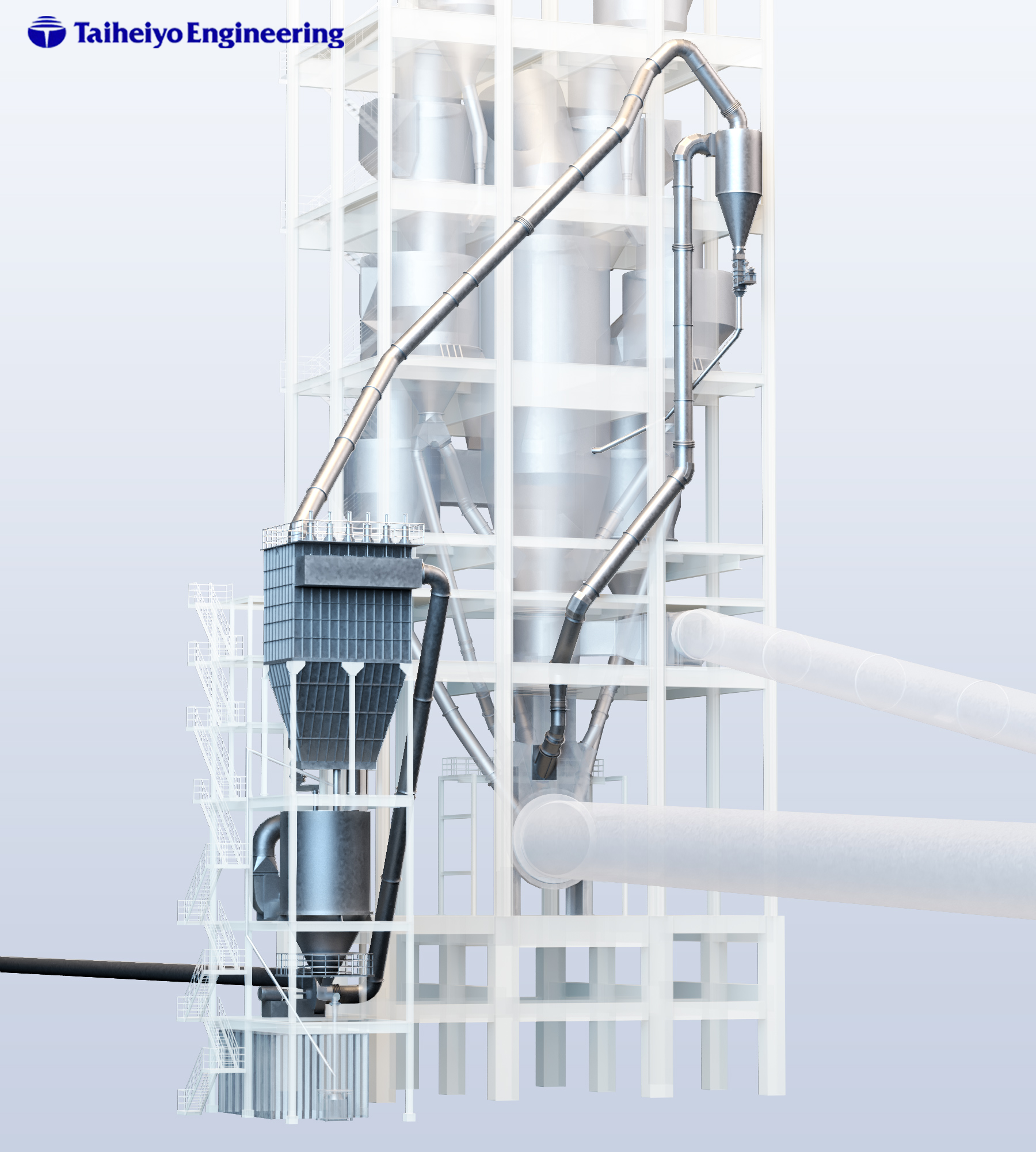

Features of TCBS Process

The main features of TCBS are as follows:

- (a) Probe

- (b) Cyclone Separator

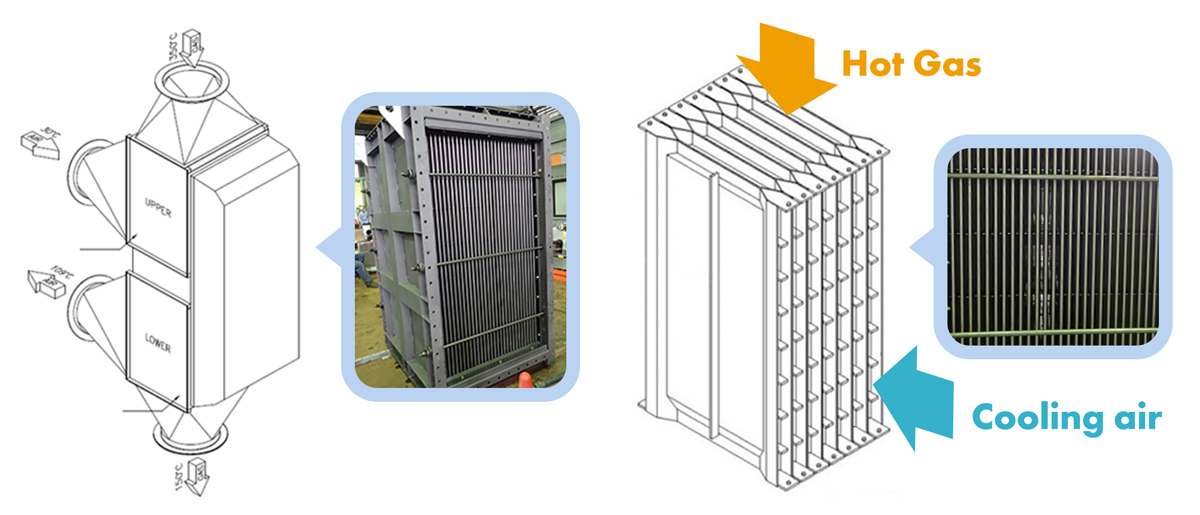

- (c) Gas Cooler (Plate type heat exchanger)

The features of TCBS are described hereunder in detail.

(a) Probe

In order to crystallize volatilized chlorine into alkali salts, the extracted gas temperature must be rapidly cooled down to 600 - 700°C, that is, lower than the melting point (770°C) of potassium chloride. The Probe lowers the temperature to below the melting point in just the first half a meter of the Probe by high speed mixing with the extracted gas and cooling air.

Rapid cooling ensures that fine dust contains more chlorine than coarse dust, minimizing the amount of chlorine returning to the clinker production line.

Moreover, the Probe is very compact, which makes it easier to install within a limited space at the kiln inlet.

(b) Cyclone Separator

Referring to the relationship between particle size distribution and chlorine concentration in bypass dust, a fair amount of the chlorine is contained in fine dust. On the other hand, the weight of fine dust covers only 15 - 20% of total bypass dust.

Owing to the Cyclone separator in TCBS, the total dust amount discharged from the clinker production line can be reduced by returning the coarse dust into the clinker production line.

If more chlorine removal is required and large dust amount discharged from the clinker production line is acceptable, it is possible to discharge the coarse dust from the clinker production line as an option.

(It is necessary to install the Cyclone separator to protect the gas cooler even when all coarse dust is discharged from the clinker production line).

(c) Gas Cooler (Plate type heat exchanger)

Owing to the Plate type heat exchanger in TCBS, the small size bag filter is applicable because it can cool the bypass gas without adding cooling air.

In addition, Plate type heat exchanger is very compact.

As a result, Gas Cooler (Plate type heat exchanger) is adopted for the Taiheiyo Chlorine Bypass System.