Recently, the regulation of NOx emission from cement plants has been

getting stricter in the world for environmental protection. To keep the regulation, many cement plants

operate SNCR (Selective Non-Catalytic Reduction) system. However, De-NOx agent (urea / ammonia) for SNCR

system is expensive and the cost burden is getting a big problem on production costs. In addition, slip

ammonia (leak ammonia) may be a problem if a lot of De-NOx agent is injected to reduce NOx emission.

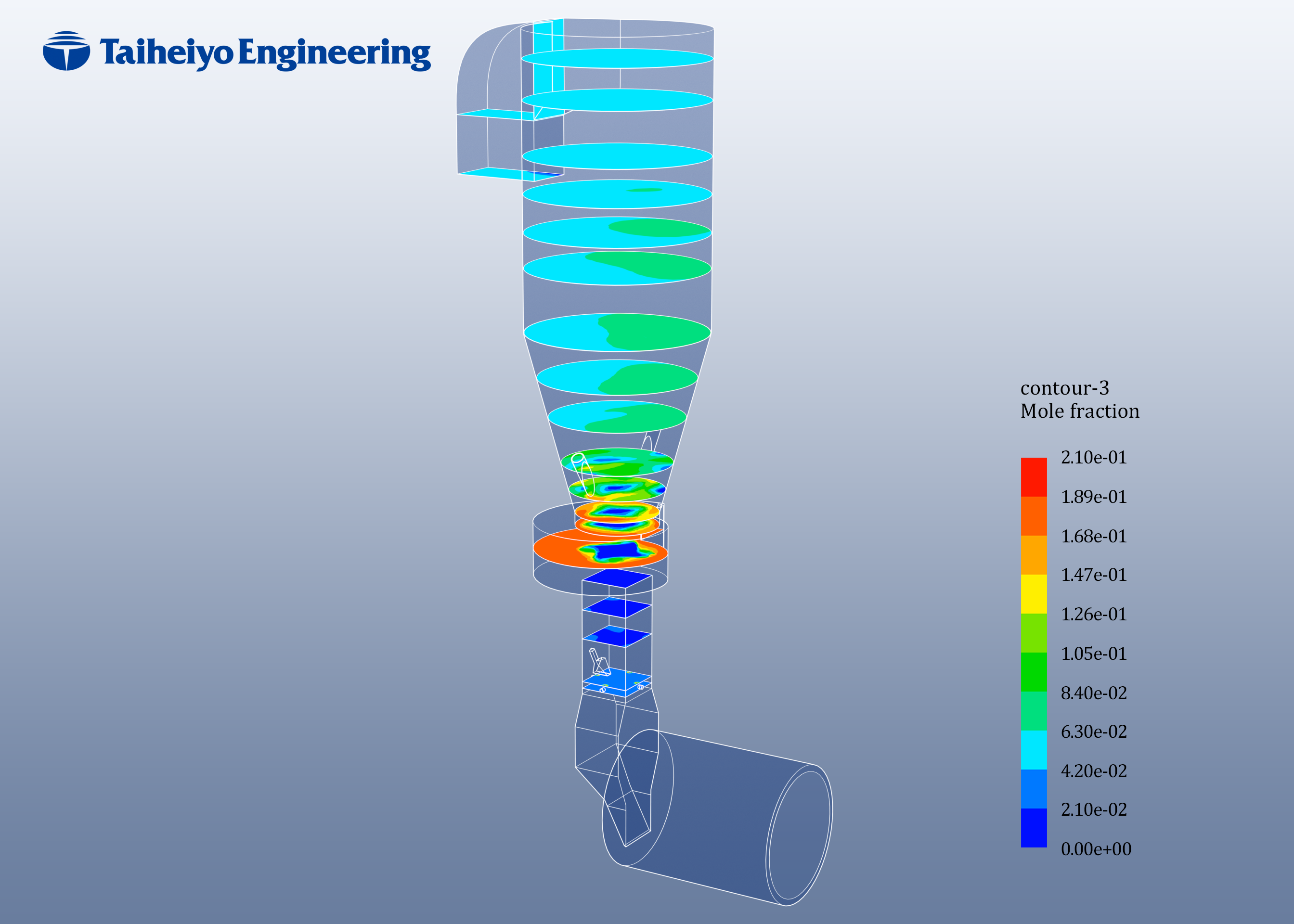

To solve such problems, Taiheiyo Engineering has developed its original two-stage combustion technology

based on researches and tests.